So, you’ve been bitten by the paramotoring bug and decided that now’s the time to take the plunge and buy your first motor.

Choosing the right paramotor can seem like a complicated decision. The options seem to know no bounds. And the online forums and Facebook groups are awash with pilots raving about their favourite paramotor brand or the latest must-have piece of kit. The challenge is sorting the wheat from the metaphorical chaff to make sure you get the best paramotor for your hard-earned cash. So we’ve broken down the different elements of the Paramotor setup that you’ll need to know about, and addresed the main questions you’ll need to consider to decide which one is right for you. When choosing your first paramotor, it’s best to wait until after you have undergone training with a qualified instructor.

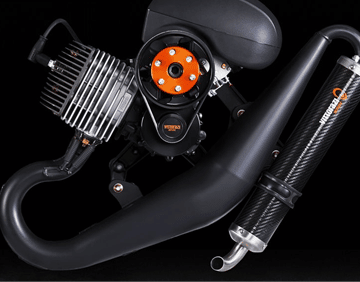

A paramotor is a paraglider wing combined typically with a 2-stroke engine and propeller , which is worn on the pilots back much like a rucksack. The motor provides enough thrust to take-off from level ground in only a few paces. Once airborne the paramotor pilot can climb and maintain level flight. The paramotor and paraglider are easily transportable, fitting into the back of a normal car.

Frame strength and easy of repair is important, especially if you are a beginner pilot. You don’t want your new pride-and-joy to buckle on the first stumble. Ensure cage diameter provides adequate clearance from propeller tips.

Aluminium airframes are light and with the right thinkness’, can be made to be extremely durable. If you do take a knock though, tubes can rarely be forced back into shape, and a more expensive repair is on the cards. The even lighter titanium airframes have a natural spring in the metal and can be bent back into shape after a quite severe misfortune.

Carbon fibre is becoming more popular with manufacturers and is extremely lightweight. Despite having an enormous strength-to-weight ratio, servere trauma to a carbon airframe usually ends in a catastrophic failure necessitating a lavish repair bill. For this reason, carbon fibre is often recommended for experienced pilots.

Thrust is the force which moves a paramotor forward, ensuring you get airborne and fly. It is important for the safety and enjoyment of your flying to choose a paramotor that has the right amount of thrust. The last thing you want is an under-powered paramotor. Your take-off runs will be longer, adding to the risk of tripping or falling, and once airborne you’ll struggle to climb safely to avoid obstacles.

Your bodyweight and stature are the primary determining factors, but there are other considerations including your physical ability to carry the paramotor, the altitude of your launch site, your flying style and your glider size.

How big your engine is and how much horsepower it has means nothing if you can’t turn that power into thrust. True, more horsepower often equates with more thrust, but prop size is quite key here too. Powerful motors are heavier and often require more fuel. More weight requires more effort to launch. Effort to haul around, and effort to exact out of your car.

So the best advice is to buy an engine that’s right for you. Your rate of climb wants to be sensible and not like an F-35 fighter jet and experience suggests that 200-300 feet per minute is enough to get out of most situations at our slow speeds. As a beginner pilot, the majority of your normal flight is going to be a leisurely cruise at around 1000 feet, not dynamic acro.

These’s plenty of choices, but as a general rule lighter pilots will typically choose a smaller engine such as the Atom 80 while pilots over 80kg favour the power of the Moster 185 Plus.

Having determined your body weight, allow 15 horsepower for the first 70 kilos. Add an additional 1 horsepower for ever 5 kilos of body weight to determine engine requirement.

As a rough guide, many pilots use the 30/70 percent rule. This means trying to use a paramotor no more than 30% of your body weight and a thrust figure of no less than 70% of the same weight. If you stick close to this equation you shouldn’t be too disappointed.

A subject that splits the paramotoring community right down the middle. With a ‘flash start’, pull starting a paramotor has never been easier for the majority of pilots. While others still prefer the convenience of simply being able to push a button to get their paramotor started. It’s worth noting that an electric starter is going to add 1.5-2kg to your overall weight. Preference may depend entirely on flying style. For example, if you plan to fly cross-country that 2kg saving is going to allow you to carry around 2.5 litres of extra fuel. Many pilots will happily sacrifice an unwieldy and uncomfortable start for almost an hour extra airtime. On the flipside, if you have a desire for acro then you may need to restart your engine in a hurry, therefore an electric start is going to be a necessary addition.

For the majority, a clutched propeller offers increased safety. The clutch prevents the propeller from spinning when the engine is idling, so there is a decreased chance of you suffering injury or damage to lines and the wing during clip-in and launch. As power is added, the clutch engages and the prop will begin to rotate. You will experience a less aggressive and slightly slower power delivery than a non-clutched propeller. During landings, it’s important to cut the engine in adequate time. A spinning prop carries plenty of energy and will cause considerable damage to your paramotor if you have a rough landing. Should the wing collapse on top of you on touchdown then the prop could catch a line and chew up your wing. It is at this point a non-clutched propeller has its advantages.

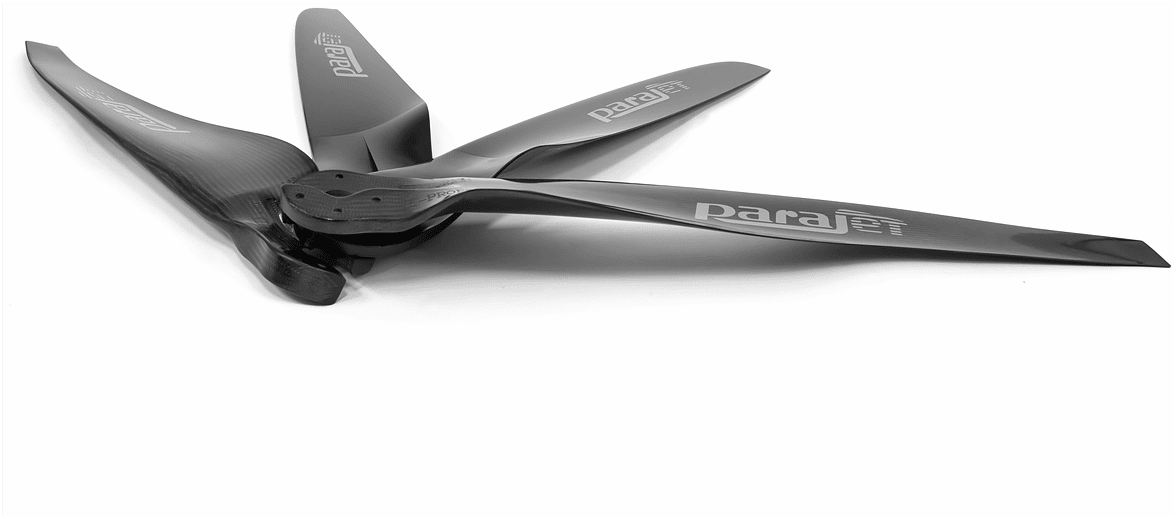

Paramotors use a fixed-pitch propeller in a variety of sizes and made from various materials. Good news for beginner pilots is that an increasing number of manufacturer’s make clear requirements as to which prop has been optimised for their engines. Any deviation from these often voids the warranty. Size of prop is influenced by the outer cage diameter. A bigger cage allows for a bigger prop, yet adds weight and becomes unwieldy to handle. The blades must fit inside the cage by a couple inches to avoid contact due to any flex.

Majority of manufacturers select carbon props. Significant weight reduction and high dimensional stability leads to better performance, improved noise reduction and less vibration. Carbon blades are extremely durable, and able to withstand multiple repairs without requiring total replacement. As a result, while carbon blades may require a higher investment upfront, they offer a better value for pilots in the long run.

The flight characteristics of your glider determine your enjoyment and overall paramotoring experience. How you connect to your glider therefore is determined by your choice of hangpoint. There are 3 main options – high, middle and low, each affecting the glider’s response feedback and handling. Modern paramotors opt for a compromise by utilising a mid-low hangpoint with articulated swan-neck arms. This places the karabiners exactly into the thrust line but eliminates power and pitch instability and offers a good amount of weight-shift. Weight-shift is the ability for you to control direction without ongoing control input. The effect of moving your body sideways affects the orientation of the pivot arms, which in turn provides input into the risers, lines and the wing. Weight-shift enables you to potentially steer ‘hands-free’ and allows you to emanate the agile characteristics of free-flight. In contrast, high hangpoints are favoured for their stability and comfort but have the disadvantage of little or no weight-shift and in some cases can also accentuate the effects of torque twist.

Choosing the right paramotor can be an intricate process, but it’s worth taking some time and doing your research. Get it right and you’ll have a paramotor that you can progress with, and one that will last for years.

Consider strength, repairability and overall weight. Lightweight makes it easier to carry, launch and everything else you’re required to do while on the ground.

Think about your body weight, and how much power and thrust you’ll need to launch and fly safely. You need to get this right, or you’ll simply struggle to get airborne.

Your choice of wing attachment determines comfort, handling and glider feedback. Articulated mid-low hangpoints offer great weigh-shift steering ability.

Do your research. Speak to your instructor. Try before you buy. Choose what’s right for you. Your safety, comfort and confidence in the air is what matters.

While the internet holds a tonne of information and is a great resource for beginner pilots, it doesn’t know everything. Asking questions and seeking out advice from your Paramotor instructor is going to yield the best opinion on which paramotor setup is right for you. They have had hundreds of students step onto their training field and you can trust their opinion.

A hang test with your instructor is highly recommended and a great opportunity to strap on your new machine and dial-in those final adjustments before leaving the ground. It is important to emulate the exact arrangement and take-off weight you’ll be during an actual flight. This will ensure that any adjustments you make to your hangpoints, thrust line and harness are accurate. This is essential for safe flight and should be done before taking your first flight, or whenever you fly a different paramotor.

Paramotor pilot and qualified instructor, Brad Ragle, has been flying for over 3 years. Check out this video where he explains why he flies and trains his students on the Parajet Maverick.

Cynthia Lecompte tells us about her experiences as a new paramotor pilot with her Parajet Maverick fitted with the Atom 80, and how great it is for female and lighter pilots. Plus, how much fun she’s had during her paramotor training!

Paul Paulikas talks about his experiences as a Parajet Maverick Atom 80 pilot and how much he enjoys flying his paramotor at the age of 79 years old, proving you can never be too old or too young to realise the dream of flight.

Paramotor pilot Greg Anthony Harris tells us about receiving and assembling his first Parajet Maverick fitted with the Atom 80 engine, how flying has changed his life and what that experience means to him.

At Parajet, we’re pilot driven. We design paramotors and paramotoring gear to make your experience awesome, especially for first time and progressing pilots. We’ve done our homework over the last two decades and have developed products that aid you in your learning process, helping you progress quickly so you can be competent, confident and safe in your flying.

Fits onto the Moster 185 Plus and Moster 185 Plus DS engines to

allow extra cooling to your cylinder head. Strongly recommended

for sportive use, for tandem flights, or for use in locations with high

temperature environments. Ships with shroud fitted.