When we look back at our history we see a series of defining moments

Our first paramotor was launched back in 2005 and our engineers have never stopped working on new ideas; with the belief that there is always a better way to solve the problems that others choose to ignore.

When we look back at our achievements we see a series of defining moments – those moments in our history which define who and what we are as a company. Take a look at some of our most influential designs and innovations that have helped shape the paramotoring industry.

The DK Whisper is a Japanese paramotor that was designed and produced by the Daiichi Kosho Company in the early nineties. Powered by the DK 472 2-stroke engine, the Whisper featured a belt reduction drive and 3-blade propeller.

In 2003, with a high degree of competition from European manufacturers DK ceased all production of the Whisper. Exclusive rights to the twin cylinder engine had been signed over to Gilo and would serve to inspire the next generation of paramotor under the brand Parajet.

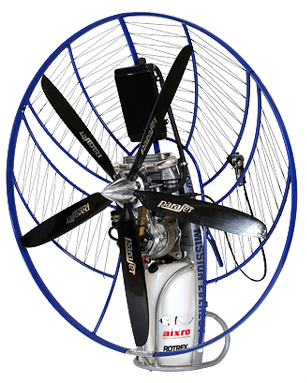

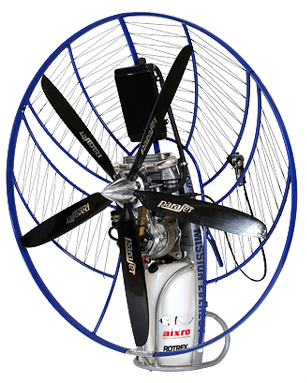

Parajet’s first paramotor was born out of the belief that it could do better. Thousands of testing hours later the Parajet Volution was launched and was the World’s first and only paramotor to be designed completely from the ‘ground up’. Meticulous assembly procedures and small in-house batch production ensured the highest level of quality and safety controls yet unseen within the industry. With hundreds of sales worldwide, the Parajet Volution was soon heralded as a milestone in paramotor evolution.

Available in three cage sizes; Micro, Compact and Macro, the Volution’s performance was matched with style, practicality and superb handling to provide an unprecedented flying experience. Every design detail was unique to Parajet – from the performance enhanced XT180 aero engine and specialised aerofoil airframe extruded from Duralumin 6082, to the carbon Scimitar low-noise prop and weight-shift anti-torque harness. When you looked around the Volution paramotor you could see the difference.

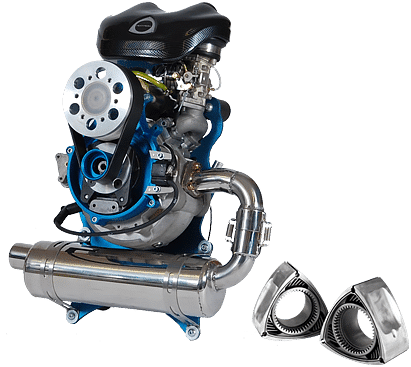

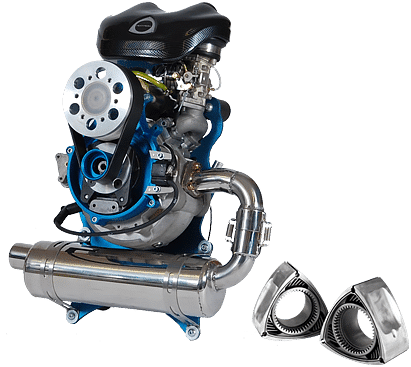

Built in just 7 months, the Mission Everest paramotor turned conventional wisdom on its head in pursuit of the ultimate test; to fly above the summit of Mt Everest, a feat many deemed impossible. The answer to the problem was to design and build a revolutionary 4-stroke rotary engine that was more compact and fifty percent lighter than a piston engine equivalent, and almost twice the reliable power output for its cubic capacity. After months of development the engine was finally ready. Two days before their departure, Gilo completed the second engine.

On the 14 May 2007, Gilo and Bear Grylls took off from the foothills of the high Himalaya, some 20 miles south of Everest in eastern Nepal, kitted out in 3-layered thermal suits and carrying equipment totalling around 120kg. Once airborne, the intrepid pair flew north, over glaciers, towards Mount Everest. Once south of the infamous Nuptse Wall, a sheer ice and rock face that soars eight thousand feet high, Gilo and Bear began to circle and ascend towards their target altitude. At around 9.30 am, with great relief and excitement Bear reached the height of 29,500ft.

Perpetual innovation is part of Parajet’s DNA and we continually look to new and emerging technologies for our future products.

Designed and developed in partnership with remote-controlled aircraft manufacturer Yuneec, the ePAC electric paramotor was the culmination of 2 years extensive research and development.

Powered by lithium polymer cells, the ePAC paramotor used a revolutionary purpose designed out-runner brushless motor. Weighing only 3.8kg, it was sensor controlled for optimum performance and reliability and represented a significant breakthrough in electric technology, offering for the first time the opportunity to fly using an environmentally friendly power source.

In 2009, an expedition team, led by Gilo and former British Army officer Neil Laughton set out on an incredible journey from London to Tombouctou. Supported by an experienced team, the 42-day expedition was an entrepid fly-drive trip through France, Spain Morocco and across the Sahara – a maiden voyage of some 6000km.

Today, the all new Parajet Xplorer flying car fuses automotive engineering with proven aviation technology to create a new generation of sports recreation vehicle designed for you to step into a new realm of adventure and discovery. An unforgettable driving experience combined with the freedom, fun and exploration of flight that will deeply inspire your emotions and fire up your senses.

Born out of the ultimate test of reliability and performance, the Parajet Cyclone built on the success of Mission Everest. At its heart the choice of either the 160cc or 294cc rotary engines.

The Cyclone’s rotary powerplant was smaller and lighter than equivalent combustion engines for its given output, and with rotating rather than reciprocating internals, considerably smoother too. Less mechanical parts and the trochoid rotor moving at only a third of the speed of the eccentric shaft meant less chances of failure, resulting in better reliability and easier maintenance. With its incredible power matched with reliability and practicality the Cyclone signified another benchmark for competitors.

In 2011, team pilot Dean Eldridge achieved an FAI Speed Record with the rotary-powered Cyclone 294, reaching an average speed of 73.84kph.

The Parajet Volution 2 took the success of its predecessor and built on it, with a stylishly updated cage netting design, overall weight reduction and more power delivered from the XT aero engine. The continued drive to move a step ahead saw the Volution 2 launch with a new lightweight paramotor harness exceeding previous levels of safety, performance and comfort.

The reduced weight and increased performance came from several core engine improvements consisting of a lighter precision balanced crankshaft manufactured from high strength EN24 steel and tempered for durability, as well as an upgraded bespoke nickel-silicon carbide cylinder casting with its 0.07mm thick coating offering superior wear characteristics and reduced friction. For those looking for an alternative to the XT powerplant, the Volution 2 became the first Parajet to follow the growing trend for Polini, Minari and Vittorazi engine fitment.

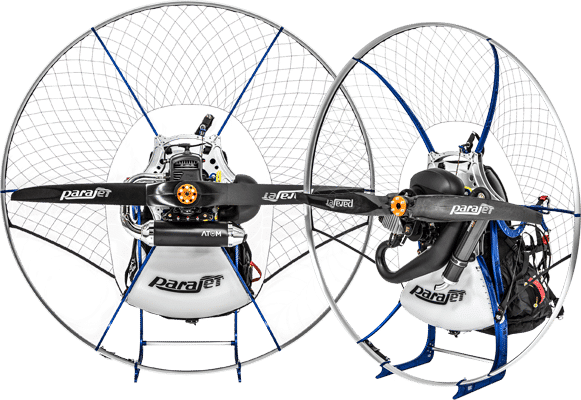

Instantly recognisable as a Parajet, the Zenith is a unique and singular design statement that has been styled and engineered to excel. Good design, however, is not just about form; it is also about function. We achieved this through the unrivaled, highest possible degree of precision manufacturing and consistency in production.

We’re used to creating products that change the paramotoring world. But with the Parajet Zenith we not only brought a new flying experience to pilots, we delivered a paramotor that was honed to be more efficient, more practical and be truly innovative.

The Zenith was engineered to perform, to find new ways to solve old problems, improving but never copying. It is a groundbreaking design that has influenced a wave of other paramotor manufacturers to follow suit and Zenith-inspired design cues can now be seen on many other paramotors throughout the industry.

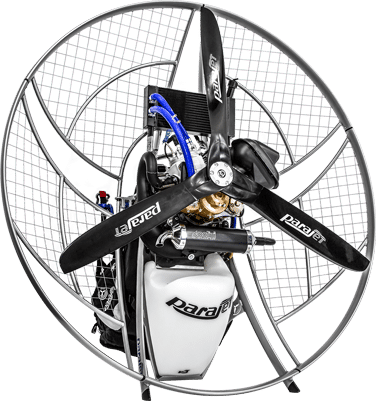

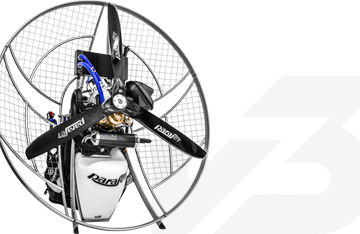

Volution 3 represents a fundamental redesign and re engineering of our most beloved paramotor; one that respects its heritage without being a slave to it. The V3’s airframe incorporates some enhanced engineering and design to improve its power-to-weight ratio and in-flight geometry allowing maximum performance without sacrificing efficiency.

The unique 4-part aerofoil cage is the defining feature, and the V3 pushes it further than ever, without compromising its great strength and rigidity. The challenge was to make it bigger without noticeably increasing the size of the cage or compromising its transportability. The sleek aerodynamic fuel tank sports a tapered design to enable the centre of mass to move closer to the thrust line improving the overall weight distribution and handling.

On the ground, the Volution 3’s wider stance offers greater stability and control so pilots can completely focus on pre-flight preparation.

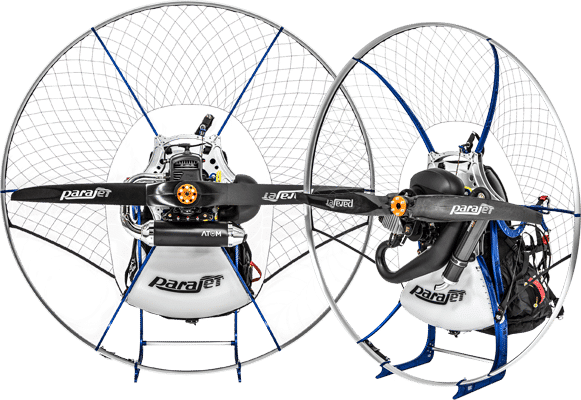

The Maverick is pure Parajet; the culmination of all the experience gained through our pioneering design, engineering innovation and paramotoring expertise. From the tapered design aesthetic of the fuel tank to the lightweight titanium airframe, every detail has been thoughtfully considered.

The slimline titanium tubing immediately gives the appearance of being light, yet the tripod structure has been optimised to be durable in all the right places. This functional design has led to a minimalist look yet delivers a remarkable flying experience. With its innovative cage and net mounting system the creativity of our design team truly shines through.

Choice is limited to a small number configurations optimised for the Vittorazi engine range – the standard Maverick fitted with the Moster Plus; Maverick Sport with a lighter e-prop, cooling shroud and travel case; the Maverick Pro with the Moster Factory; and the Maverick Atom 80 for those pilots less than 85kg.